In industrial automation, alarms are the lifeline between process conditions and operator action. They provide the early warnings that help prevent accidents, reduce downtime, and maintain process quality. However, when alarm systems are poorly designed or overloaded, they can do more harm than good.

Excessive, irrelevant, or improperly prioritized alarms can lead to a phenomenon known as alarm fatigue. This occurs when operators are exposed to so many alerts that they begin to ignore them—sometimes missing the critical few that signal real danger. The results can be catastrophic: safety incidents, costly downtime, regulatory non-compliance, and damage to equipment.

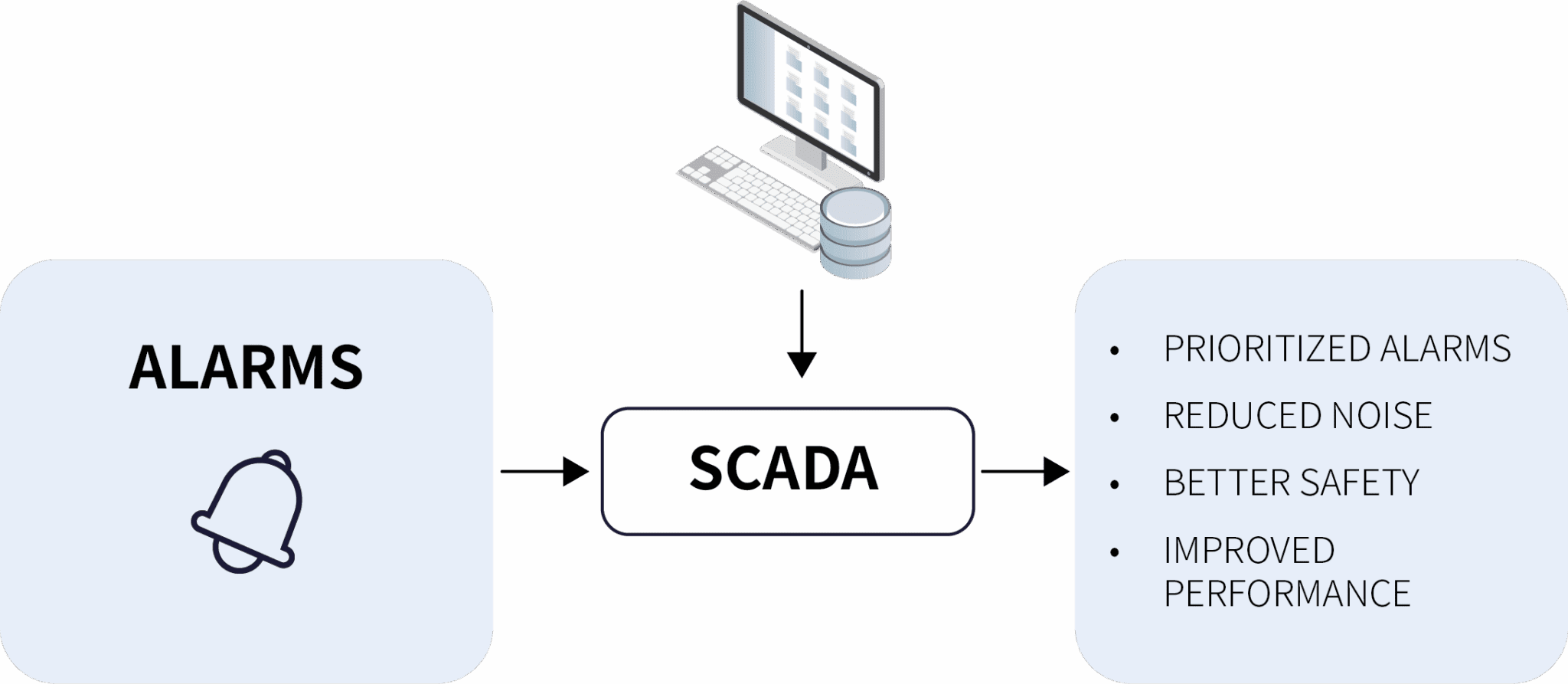

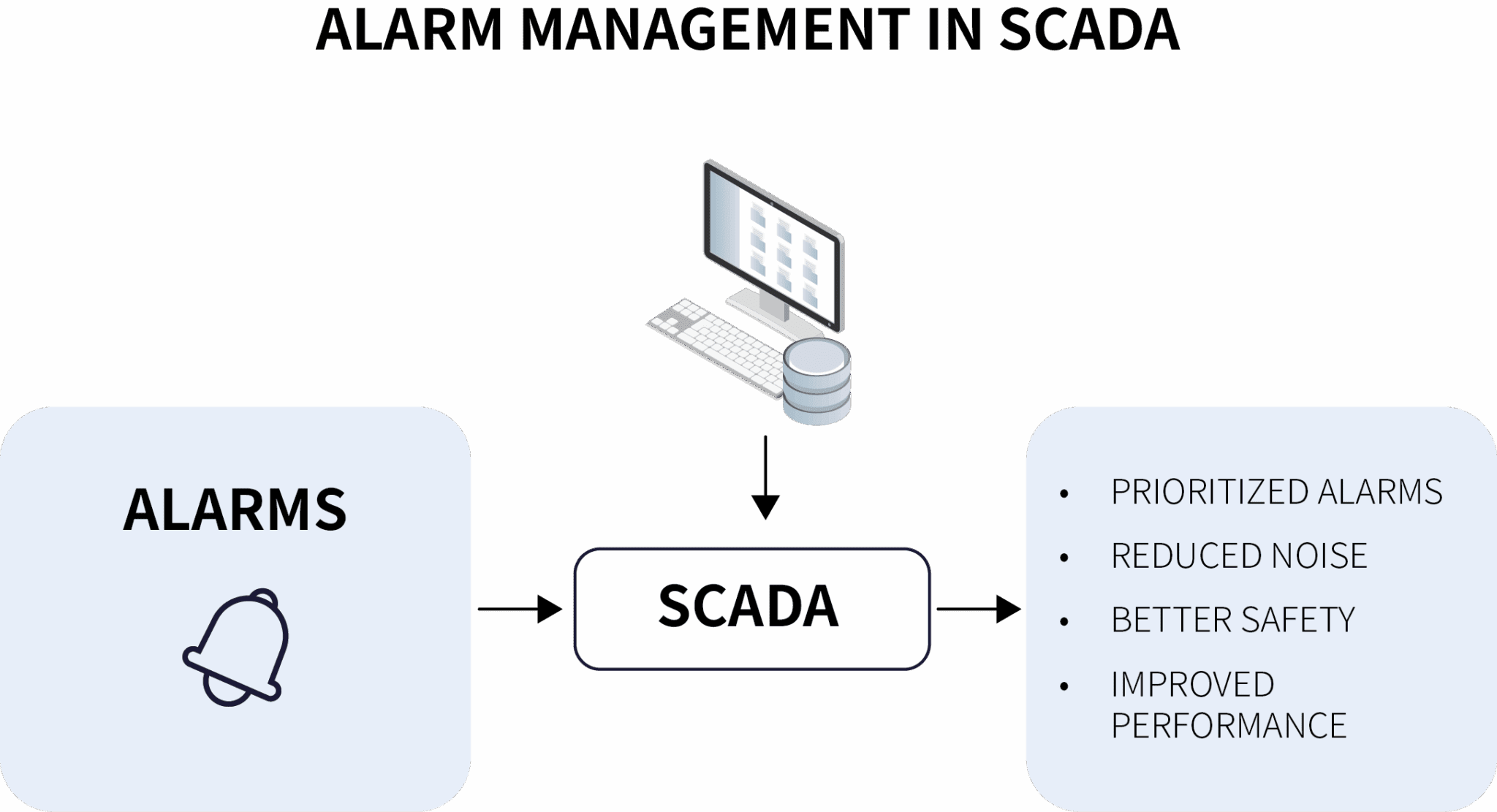

The ISA 18.2 standard was created to address these challenges. By defining a structured alarm management lifecycle, it provides a framework to ensure alarms are meaningful, actionable, and properly managed over the lifetime of a system. When implemented within a modern SCADA platform, ISA 18.2 transforms the alarm system from a noisy distraction into a strategic operational tool.

Understanding Alarm Fatigue in Industrial Environments

The Problem of Too Many Alarms

Imagine a chemical plant where every small fluctuation triggers an alert. Pumps starting and stopping, valves moving, temperature spikes lasting milliseconds—all generate alarms. Operators must constantly acknowledge these alerts, leaving them less attentive to real process deviations.

The Risks

- – Slower response to critical events due to distraction.

- – Increased human error, as operators miss or misinterpret alerts.

- – Regulatory compliance issues, since many industries require documented alarm performance.

- – Operator stress and burnout, impacting long-term workforce performance.

The ISA 18.2 Framework

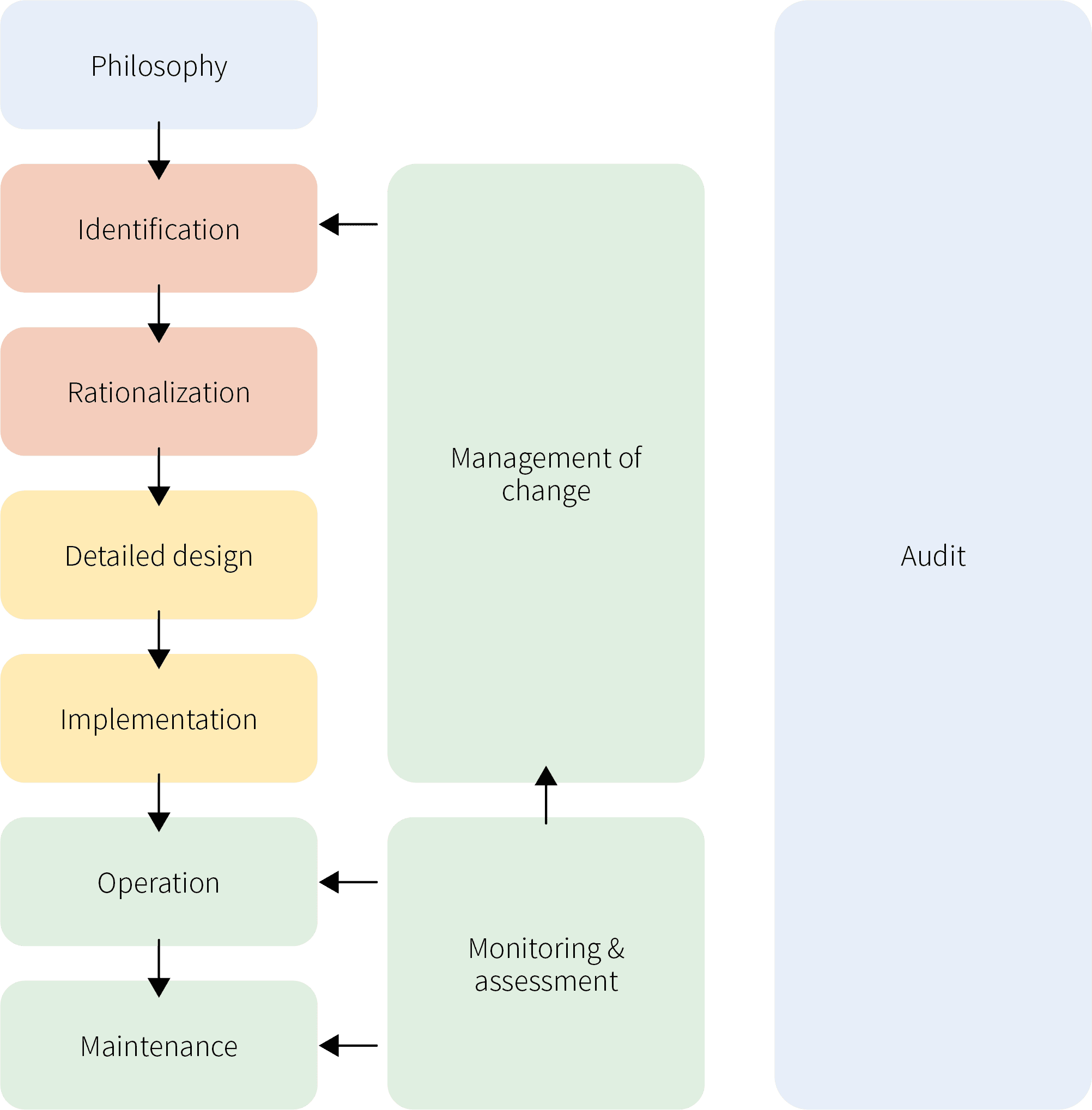

ISA 18.2 defines nine key stages in the alarm management lifecycle:

- – Alarm Philosophy: Define organizational goals, criteria for alarms, and system design principles.

- – Identification: Decide which process conditions should trigger alarms and why.

- – Rationalization: Review alarms to ensure they are necessary, properly classified, and prioritized.

- – Detailed Design: Specify setpoints, hysteresis, and the text of messages presented to operators.

- – Implementation: Configure alarms within the SCADA system according to design specifications.

- – Operation: Ensure alarms are monitored, acknowledged, and acted upon by trained operators.

- – Maintenance: Adjust or disable alarms as equipment or processes change.

- – Monitoring & Assessment: Track alarm KPIs such as frequency, standing alarms, and operator response time.

- – Audit: Periodically review the entire alarm system to ensure ongoing compliance and performance.

SCADA Features That Support ISA 18.2 Compliance

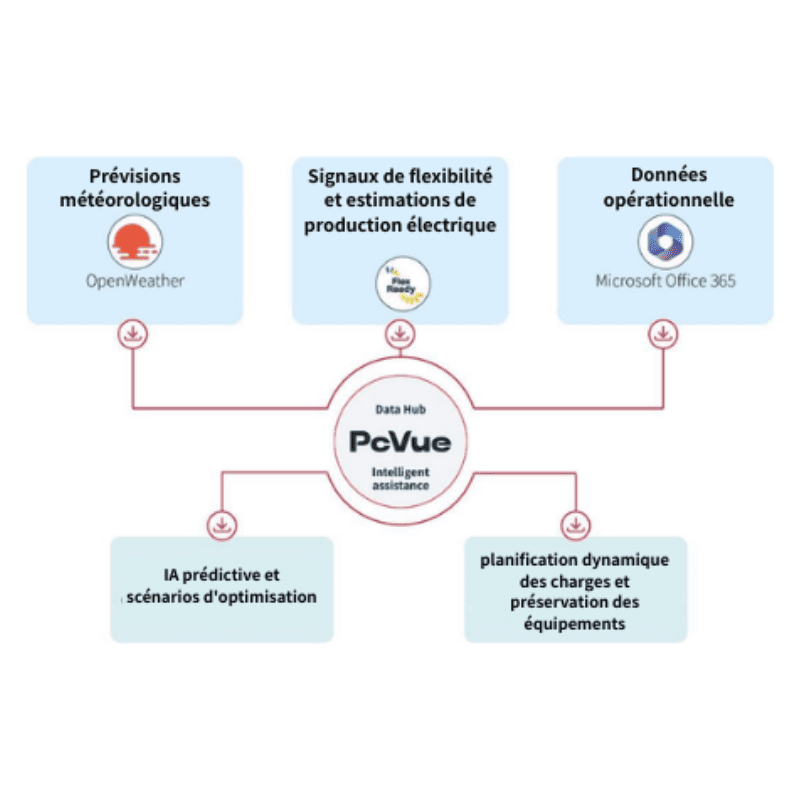

A modern SCADA platform such as PcVue can embed ISA 18.2 principles directly into alarm management. Key capabilities include:

1.Alarm Prioritization

Not all alarms are equal. SCADA can enforce rules that ensure high-priority alarms—those affecting safety or production—are highlighted, while low-priority events are presented less intrusively.

2. Alarm Suppression and Shelving

Operators can temporarily suppress alarms during known non-critical events (maintenance, startup, testing) to reduce nuisance alerts without disabling critical protections.

3. Event Filtering and Grouping

SCADA can group related alarms, helping operators see the bigger picture rather than reacting to a flood of separate messages.

4. Performance KPIs

Built-in analytics can track metrics such as:

- – Average alarms per hour

- – Number of standing alarms

- – Operator acknowledgment times

These KPIs help identify and resolve systemic alarm issues.

5. Audit Trails and Reporting

Automated reporting ensures regulatory compliance and supports continuous improvement by documenting alarm changes, acknowledgments, and operator actions.

Operational Benefits of ISA 18.2-Compliant SCADA

Improved Operator Performance

By reducing alarm noise and ensuring that only actionable alerts are presented, operators can respond more quickly and accurately to process deviations.

Increased Safety and Reliability

With clear, prioritized alarms, critical safety events are less likely to be overlooked. This reduces the risk of accidents and unplanned downtime.

Cost Reduction

Better alarm management reduces unnecessary shutdowns, improves maintenance scheduling, and optimizes resource allocation.

Regulatory Compliance

Many industries—such as oil & gas, chemicals, pharmaceuticals, and power generation—are subject to strict alarm performance requirements. ISA 18.2-compliant SCADA provides the necessary auditability.

Example Use Case: Chemical Plant Rationalization Project

A large chemical manufacturing facility operated with over 6,000 configured alarms. Operators were receiving over 200 alarms per hour during normal operation. After implementing ISA 18.2-based rationalization within their SCADA system:

- – Alarm count dropped to fewer than 500 active alarms.

- – Alarm rate was reduced to fewer than 10 per hour in normal conditions.

- – High-priority alarms were clearly distinguished with unique colors and sounds.

- – Response time to critical events improved by 35%.

Integration with Other Standards

ISA 18.2 does not exist in isolation. It aligns with IEC 62682 (the international equivalent) and can be integrated into a broader control system management strategy alongside:

- – ISA 84 / IEC 61511 for Safety Instrumented Systems.

- – NERC CIP standards for cybersecurity in the power sector.

- – ISO 9001 for quality management.

Continuous Improvement Through SCADA Analytics

Modern SCADA platforms do more than just display alarms—they can analyze trends and suggest improvements. For example:

- – Frequent Alarm Analysis: Identifying devices that cause repeated alarms and prioritizing maintenance.

- – Flood Detection: Recognizing alarm storms that overwhelm operators and triggering automated response modes.

- – Operator Load Monitoring: Ensuring alarm presentation matches human processing capabilities.

Why ISA 18.2 Compliance is a Competitive Advantage

In a competitive industrial environment, plants that operate safely and efficiently enjoy lower operating costs, fewer incidents, and better regulatory standing. Implementing ISA 18.2 with SCADA not only meets compliance requirements but also delivers measurable business value:

- – Enhanced productivity through reduced downtime.

- – Stronger customer and regulatory confidence in operational integrity.

- – Long-term scalability, as well-managed alarm systems adapt more easily to plant expansions or process changes.

Conclusion

Alarms are not just noise—they are a vital decision-making tool. But without structure, they can overwhelm operators and compromise safety. The ISA 18.2 standard offers a clear, proven path to designing and managing alarm systems that work for, not against, your operations.

A SCADA platform designed with ISA 18.2 principles built in delivers:

- – Prioritized, actionable alarms.

- – Reduced operator workload.

- – Continuous improvement through KPIs and analytics.

- – Long-term compliance and safety assurance.

In short, it transforms alarms from a liability into a strategic asset—ensuring your plant operates safely, efficiently, and with the confidence that every alarm truly matters.

| File name: | https://www.pcvue.com/wp-content/uploads/2025/09/PcVue-SCADA-Compliance-with-ISA-18.2-Alarm-Management-Standard.pdf |

| File size: | 1.47 MB |

| File type: | |

| Hits: | 952 Hits |

| Downloads: | 41 Downloads |

| Created Date: | 2 Sep 2025 |

| Last Updated Date: | 24 Sep 2025 |

-

Tags Under

- Alarms

- ISA-18.2

- alarm management standard