Customer Overview

Luxshare Precision was founded on May 24, 2004. It specializes in providing integrated intelligent manufacturing solutions for consumer electronics, automotive products, and enterprise communications—from core components and modules to system assembly. The Kunshan factory under Luxshare Precision features fully automated production lines and Class 10,000 cleanrooms. The products demand micron-level precision and extremely stable production environments.

Project Background and Challenges

With a surge in order volume, the Kunshan factory faced multiple challenges under the traditional manual operation and maintenance model:

– High Labor Costs: Equipment in the workshop required 24-hour manual inspection, with dedicated O&M personnel per production line, leading to extremely high annual labor costs.

– Delayed Fault Response: Equipment failures and environmental fluctuations relied on manual detection, resulting in long average response times.

– Environmental Monitoring Blind Spots: Precision semiconductor production requires temperature control at 22°C and humidity at 45% RH (Relative Humidity). Traditional instrumentation had blind spots, and local fluctuations sometimes exceeded thresholds.

– Severe Data Silos: Equipment data was scattered across isolated systems, making it impossible for management to obtain real-time, holistic production status.

To achieve intelligent upgrades, the Kunshan factory launched a comprehensive smart monitoring system project, introducing PcVue through Moran Automatic Control System (Shanghai) Co., Ltd. The entire project took six months to complete and covered full-facility deployment of intelligent systems.

Solution & Results

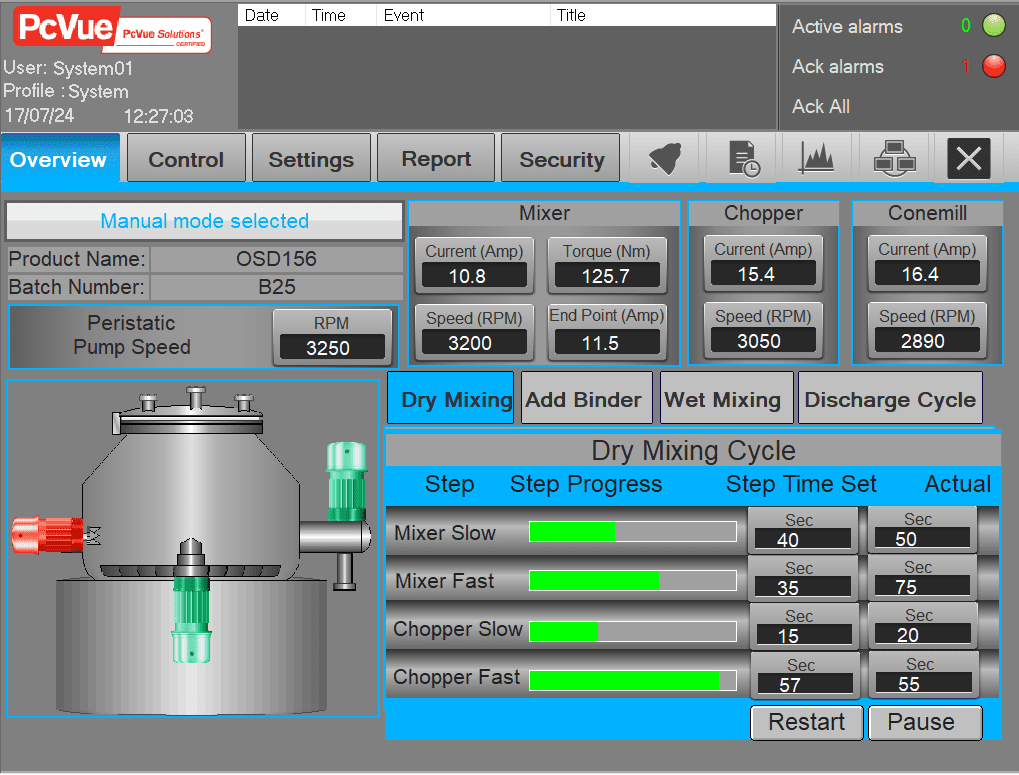

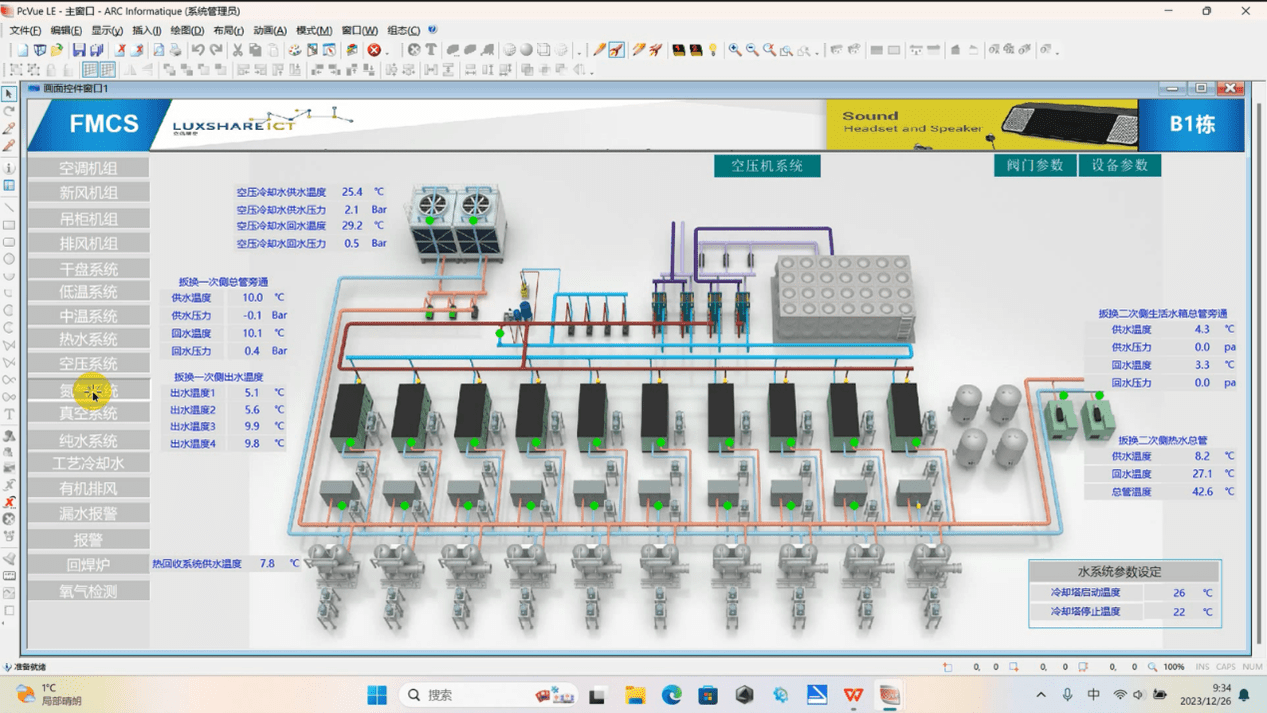

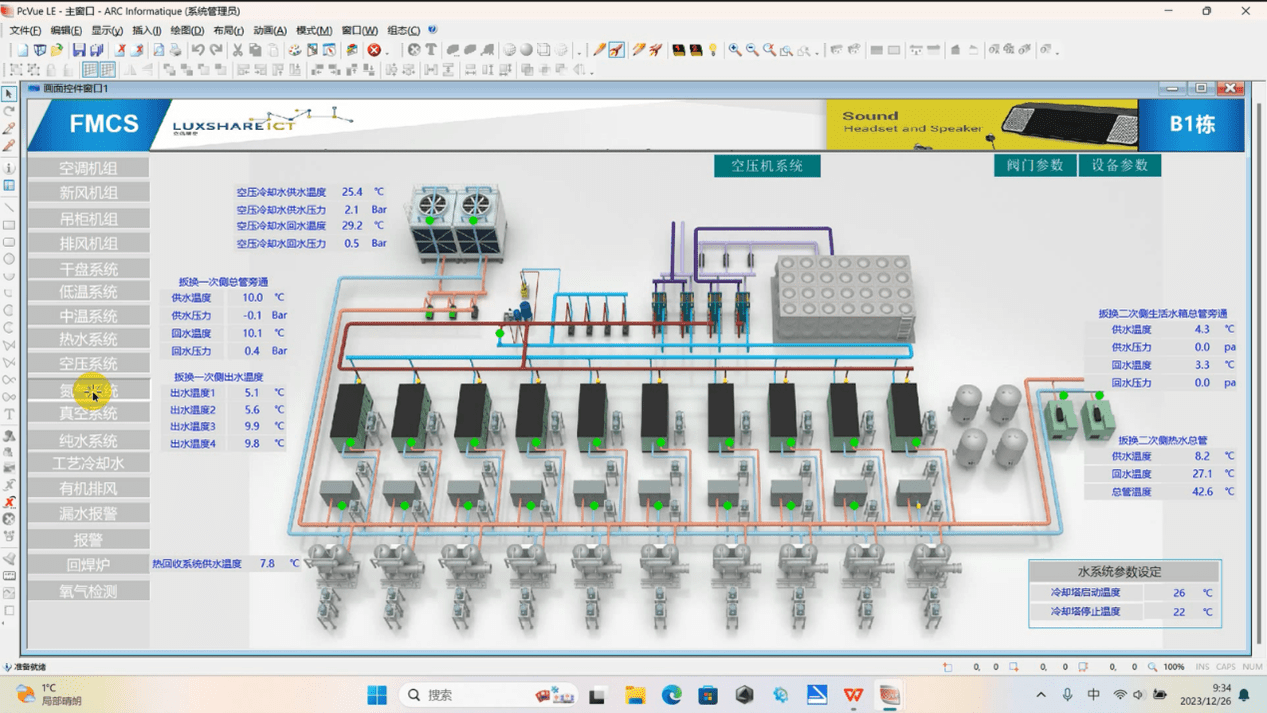

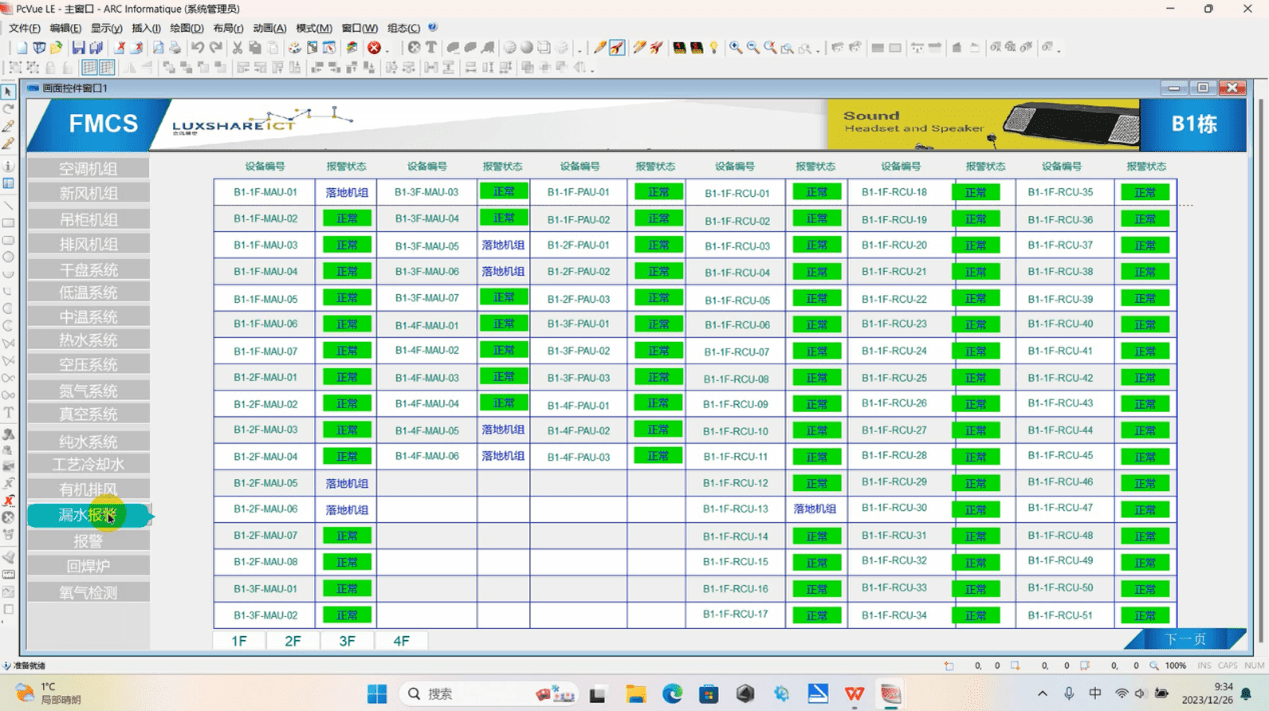

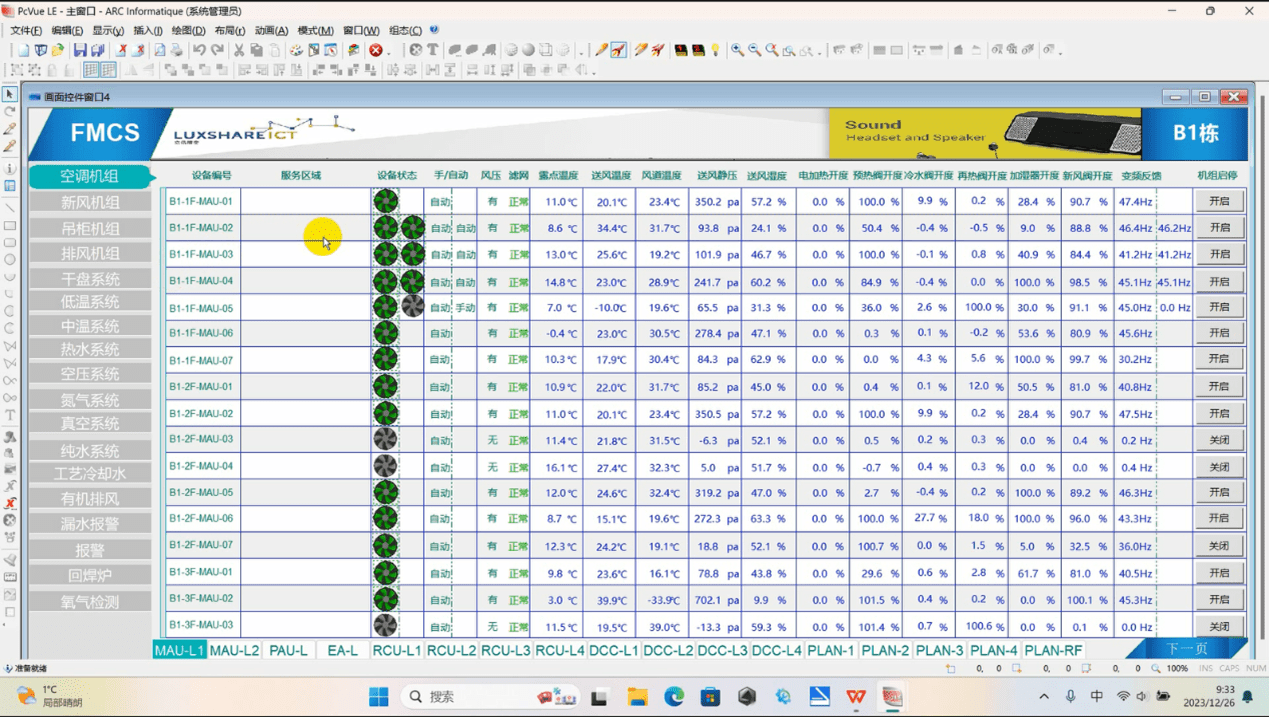

– Real-Time End-to-End Monitoring

PcVue integrates equipment data to visualize production parameters (pressure, temperature, speed) in real-time.

– Smart Alerts and Quick Response

Predictive maintenance through historical data modeling and health thresholds significantly reduced downtime due to faults. Alerts for abnormal events were promptly pushed, greatly reducing response times.

– Automated Workflow Optimization

Integrated with the FMCS system (Factory Manufacturing Control System) to automatically dispatch work orders and sync production progress. When temperature or humidity exceeds limits, the system automatically adjusts air conditioning units to improve efficiency.

Project Highlights

– Modular Deployment: Full-factory transformation completed in 6 months without disrupting normal production.

– User-Friendly Interface: Customized interfaces lowered training costs for staff.

Together with Moran Automation, PcVue enabled the digital and intelligent transformation of Luxshare Precision’s Kunshan factory, significantly reducing operational costs and enhancing product quality and market competitiveness. This project stands as a benchmark for “smart factory” construction in the electronics and semiconductor industry.

Looking to improve your SCADA system efficiency?

| File name: | https://www.pcvue.com/wp-content/uploads/2025/07/CSS_Industry_Luxshare_EN.pdf |

| File size: | 1.60 MB |

| File type: | |

| Hits: | 564 Hits |

| Downloads: | 2 Downloads |

| Created Date: | 21 Jul 2025 |

| Last Updated Date: | 8 Oct 2025 |